Wheel Grit Diamond Powder

Polycrystalline synthetic diamond powder utilizes good toughness, and can maintain high grinding force while not prone to scratches during the grinding and polishing process. It is widely used in the grinding and polishing of various hard materials such as optical crystals, ceramics, and super-hard alloys.

Description

Synthetic diamond powder is a new type of super-hard and ultra-fine abrasive formed by special processing and processing of synthetic diamond single crystal. It is an ideal raw material for grinding and polishing high-hardness materials such as cemented carbide, ceramics, gems, and optical glass. Industrial syntheic diamond powder is widely used in making all kinds of diamond tools, such as wire saw, diamond grinding wheels etc. Synthetic diamond grit and its products are widely used in automobile, machinery, electronics, aviation, aerospace, optical instruments, glass, ceramics, petroleum, geology and other sectors. With the continuous development of technology and products, the use of synthetic diamond dust and products is still expanding.

Applications of Industrial Synthetic Diamond Powder

Grinding and Polishing: Due to its extreme hardness and abrasiveness, it is an ideal material for sharpening, grinding and abrasive processes. It is commonly used to sharpen tools, create precision optical lenses, polish gemstones, and prepare surfaces for coating or painting.

Cutting and Sawing: Synthetic diamond powder is essential in the production of cutting tools, such as saw blades, wire saws, and drill bits. It provides the necessary hardness and durability required for cutting through materials like stone, concrete, metal, and glass with precision and efficiency.

Electronics and Semiconductors: It is utilized for applications such as creating heat sinks, polishing surfaces for integrated circuits, and increasing the efficiency of heat dissipation in high-performance electronic devices.

Thermal Management: The outstanding thermal conductivity of synthetic diamond powder makes it an ideal material for thermal management applications. It is used in heat spreaders and heat sinks to efficiently transfer and dissipate heat in electronic devices, power modules, LED lighting, and other high-temperature applications.

Lubrication and Coatings: synthetic diamond grit can be used as a lubricant additive due to its excellent friction-reducing properties. It is also used as a coating material on cutting tools to enhance their performance and longevity. The diamond coating provides high wear resistance, reducing the need for frequent tool changes and increasing overall productivity.

- Our Main Models for Producing Wheel Grit

-

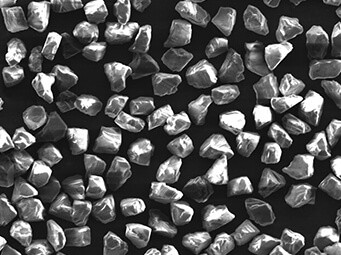

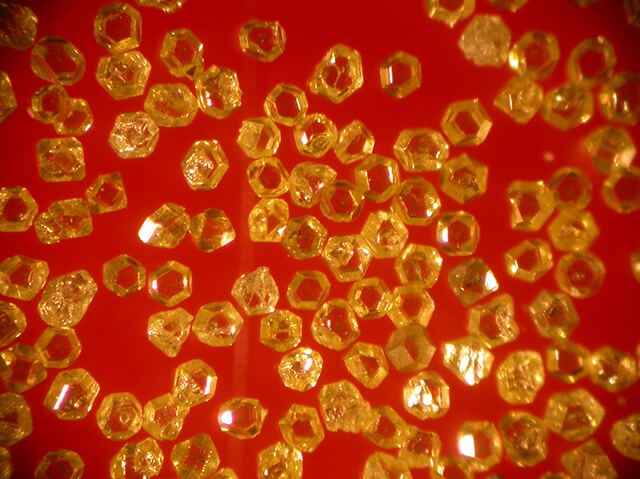

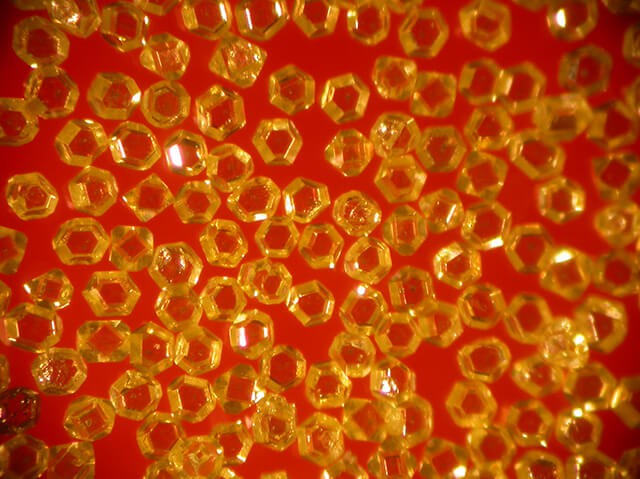

- HFD - D/C

- Complete cubo-octahedron crystals with regular shape and good transparence. Applied to make high quality professional tools, like electropiated tools, grinding wheels, glass drill bits, and to polish and curve stone and process car glass, high grade furniture, ceramic, alloy, magnetic materials etc.

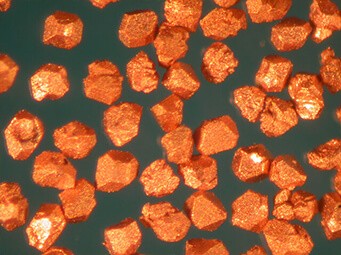

- HFD - B/A

- Comparatively regular shape, good transparence, mainly used for producing medium grade diamond tools, like metal bond or vitrified bonding grinding wheels, abrasive wheels and medium grade electroplated tools to process carbide, ceramic, magnetic materials, glass etc.

Free quote is offered for worldwide customers, and delivery is also very fast. Huanghe Whirlwind is a famous brand in China, which is a leading manufacturer in the production and innovation of synthetic diamond powder with its own large factory and high standard innovation team. Contact us for inquiry if in need of diamond powder!

Specification

| HFD Series | ||||

| TYPE / SIZE | 100/120 | 120/140 | 140/170 | 170/200 |

| HFD-A | Y | Y | Y | Y |

| HFD-B | Y | Y | Y | Y |

| HFD-C | Y | Y | Y | Y |

| HFD-D | Y | Y | Y | Y |

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский