Metal Powder – Universally Used

Huanghe Whirlwind has its own separate metal powder production department, which advocate healthy and environmental production all the time. Our metal powders are well-welcomed both at home and abroad, and it has been exported to worldwide countries, such as Italy, America, Iran, India, Thailand, Malaysia, Japan, Korea etc.

Description

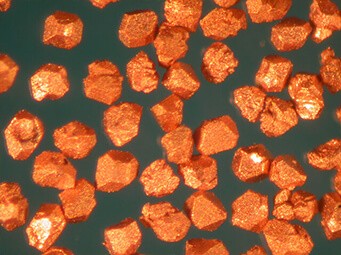

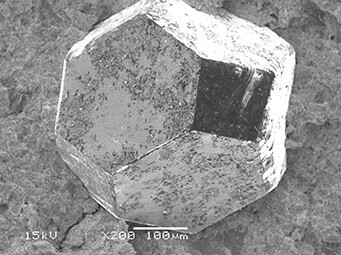

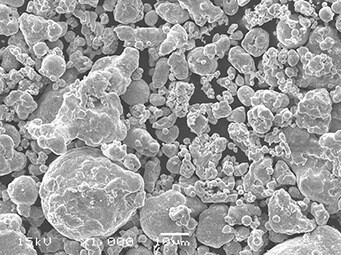

Metal powder refers to finely ground particles of metallic elements or alloys. It is produced through various methods such as atomization, chemical reduction, or mechanical milling. Metal powders have a wide range of applications across industries due to their unique properties and versatility. They can be used as raw materials for manufacturing processes like powder metallurgy, additive manufacturing (3D printing), surface coating, and chemical reactions.

Metal powders offer advantages such as high surface area-to-volume ratio, improved reactivity, and enhanced mechanical properties. They can be tailored to meet specific requirements by controlling factors like particle size, shape, and composition. Common metals used in powder form include iron, aluminum, copper, titanium, nickel, and stainless steel.

In powder metallurgy, metal powders are compacted and then sintered to create solid components with desired shapes and properties. Additive manufacturing utilizes metal powders to build complex structures layer by layer, enabling the production of intricate parts with high precision. Metal powders are also used in surface coating applications to provide corrosion resistance, wear resistance, or aesthetic finishes.

We offer complete metal powder specifications that can totally satisfy your purchase demand. Besides that, our metal powders for sale are cost-effective, which can greatly enhance the performance of diamond tools with less cost. Different types of metal powders have specific usage and application.

- JF01

-

Applicable to all types of diamond tools, as a base powder to reduce the cost of diamond tools, cost-effective, the carcass has a strong mechanical inclusion of diamond, good sharpness.

- JF02

-

Applied to various types of diamond tools, the self-sharpness of the carcass, the mechanical inclusion of the carcass to diamond, and the integrated performance of the diamond tools are improved.

- JF16

-

Applied to various types of diamond tools, as a base powder is added to the sintering formula, the cost of diamond tools is reduced, good cost-effective, the carcass has a strong mechanical inclusion of diamond, and the sharpness is good.

- JF77

-

Applied to various types of diamond tools, the self-sharpness of the carcass, the mechanical inclusion of the carcass to diamond, and the integrated performance of the diamond tools are improved.

- FQSn10

-

- Performance characteristics

- 1. Production of diamond tools are applied.

- 2. Oil-bearing bearings, friction materials and other industries are applied.

- HYF-CS

-

- Performance characteristics

- 1. Preparation of copper-tin alloy powder by atomization method, high-grade copper-tin alloy products, alloy powder structure is adjusted by special rare earth, powder has low oxygen content, good fluidity and good cold forming property.

- 2. Pre-alloyed powder is used to prepare diamond tools and can replace 50% tin powder. When the sintering temperature is increased, the loss of the carcass tin powder is reduced, and the production cost is lowered.

-

These are our metal powders for universally use, and we also offer other types of metal powders for sale, such as stainless steel powder, flux-cored wire using metal powder, oil-retaining bearing using bronze powder, diamond synthesis using catalysis powder, metal powder for diamond wire and other diamond tools. Contact us for Free quotation now! Low price and top performance!

Specification

| Model | Main element | Theoretical density | Sintering temperature | Bending strengt | Hardness |

| JF-01 | Fe、Cu | 8.16g/cm³ | 830℃ | 1350MPa | 98-104HRB |

| JF-01G | Fe、Cu | 8.16g/cm³ | 830℃ | 1300MPa | 95-100HRB |

| JF-02 | Fe、Cu | 8.27g/cm³ | 780℃ | 1350MPa | 94-99HRB |

| JF-16 | Fe、Cu | 8.06g/cm³ | 850℃ | 1300MPa | 95-100HRB |

| JF-37 | Fe、Cu | 7.89g/cm³ | 850℃ | 1000MPa | 85-95HRB |

| HJF922 | Fe、Cu | 7.96g/cm³ | 870-890℃ | 1250-1450MPa | 100-105HRB |

| HJF923 | Fe、Cu、Sn | 7.92g/cm³ | 810-840℃ | 1250-1450MPa | 104-109HRB |

| HJF925 | Fe、Cu、Zn | 8.01g/cm³ | 830℃ | 1200MPa | 100-105HRB |

| SF-321 | Fe、Cu、P | 7.81g/cm³ | 850℃ | 1600MPa | 105-110HRB |

| SF-341 | Fe、Cu、Sn | 7.7g/cm³ | 830℃ | 1400MPa | 104-108HRB |

| HD-03 | Fe、Cu、Ni、Sn | 7.99g/cm³ | 830℃ | 1300MPa | 104-108HRB |

| HYF-05 | Fe、Cu、Sn | 8.19g/cm³ | 770℃ | 1100MPa | 98-104HRB |

| HYF-06 | Fe、Cu、Ni、Sn | 8.08g/cm³ | 810℃ | 1300MPa | 104-109HRB |

| HYF-07 | Fe、Cu、Co、Sn | 7.84g/cm³ | 790℃ | 1500MPa | 105-110HRB |

| HYF-20 | Fe、Cu、Sn | 7.9g/cm³ | 830℃ | 1400MPa | 104-108HRB |

| HYF-25 | Cu、Co、Sn | 8.29g/cm³ | 760℃ | 800MPa | 85-95HRB |

| HYF-58 | Fe、Co、Cu | 8.59g/cm³ | 850℃ | 1500MPa | 103-107HRB |

| HYF-88 | Fe、Cu、Sn | 7.71g/cm³ | 850℃ | 1350MPa | 107-113HRB |

| HWF-506 | Fe、Ni、Cr | 7.85g/cm³ | |||

| JF-26 | Fe、Cu、Ni | 8.23g/cm³ | 870℃ | 1400MPa | 105-112HRB |

| JF-77 | Fe、Cu、Ni、Sn | 8.07g/cm³ | 780℃ | 1200MPa | 106-110HRB |

| HYF-CS | Cu、Sn | 8.05g/cm³ |

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский