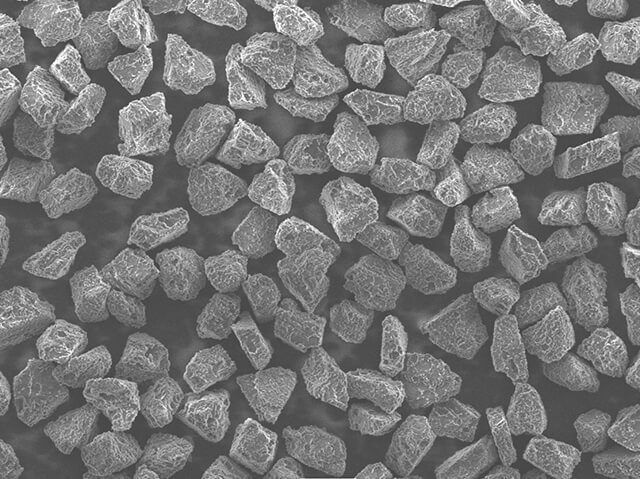

Diamond Micron Powder

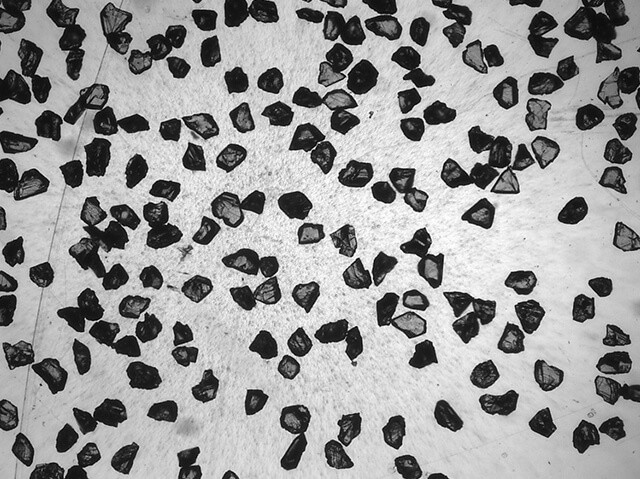

Diamond micron powder is a fine-grained synthetic diamond material that is used in various precision applications. It is produced by carefully processing high-quality diamonds into tiny particles with consistent size and shape. Micron diamond powder is an ideal raw material for grinding and polishing high-hardness materials such as cemented carbide, ceramics, gems, and optical glass.

Description

Diamond micron powder finds extensive use in industries such as electronics, optics, telecommunications, and precision machining. It is commonly employed in processes like lapping, polishing, and superfinishing of various materials, including metals, ceramics, glass, and semiconductors.

The small particle size of diamond micron powder allows it to effectively remove material and achieve precise surface finishes without causing excessive damage or scratching. It is often used in the production of optical lenses, electronic components, and precision tools where smoothness and accuracy are critical.

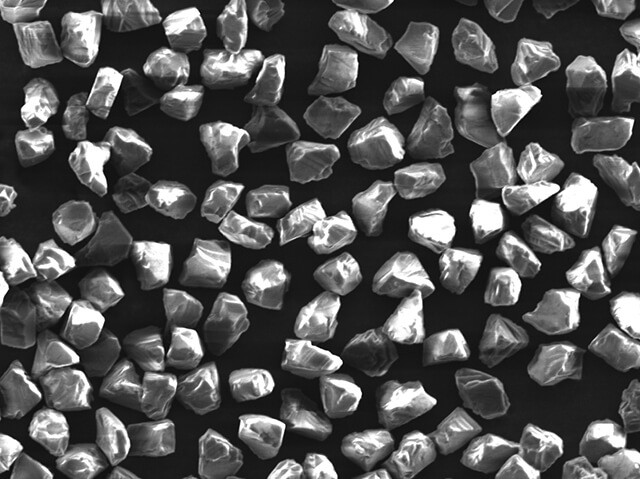

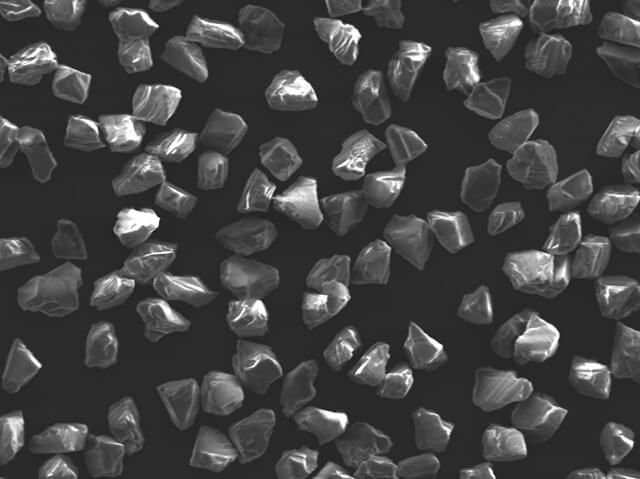

Diamond micron powder offers several advantages over other abrasive materials. It provides excellent cutting and polishing performance, exceptional hardness, and wear resistance. Its uniform particle size distribution ensures consistent results and reduces the risk of surface defects.

Diamond micron powder produced by Huanghe whilrwind has high hardness and good wear resistance. Micron Diamond powder is suitable for the production of high-quality diamond tools such as PCD, high-quality abrasive paste, high-grade diamond spray, suspension and other products, and the processing of natural diamonds, stone, ferrous metals and other products.

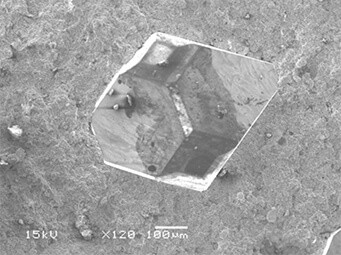

Huanghe Whirlwind is the main domestic producer of high-quality single crystal diamond powder, cubic boron nitride powder and micron diamond powder. As an expert in the production of super-hard abrasive powder, Huanghe Whirlwind has always implemented the management concepts of 6S, 5S and IS09002 throughout the production process. Our production line is equipped with advanced modern instruments, such as topography analysis system, plasma ICP detector, Laser particle size analyzer, SEM, etc.

Huanghe Whirlwind's control of the quality of diamond micro powder has completely entered the world of microscopic particles throughout the various stages of crushing, shaping, cleaning, classification, purification, identification, storage and transportation. Our coating technology on micro-powder is also in a leading position, with high surface roughness, uniformity and particle size distribution. Welcome to contact us for more detailed info of diamond micron powder for sale, and free quote is offered for worldwide customer!

Specification

| JB/T7990-1979 | GB6966-86 | JB/T7990-1998 | QB/HH-2004 | Corresponding Mesh |

| 0-0.25 | ||||

| WO.5 | 0-0.5 | M0/0.5 | 0-0.5 | |

| W1 | 0-1 | M0/1 | 0-1 | |

| M0.5/1 | 0.5-1 | |||

| 0.5-1 | M0.5/1.5 | 0.5-1.5 | ||

| 0.5-1.5 | M0/2 | 0-2 | ||

| W1.5 | 0-2 | M1/2 | 1-2 | |

| 0.5-3 | 12000 | |||

| W2.5 | 1.5-3 | M1.5/3 | 1-3 | 10000 |

| 1.5-3 | 8000 | |||

| 2-3 | 7000 | |||

| W3.5 | 2-4 | M2/4 | 2-4 | 6000 |

| W5 | 2.5-5 | M2.5/5 | 2-5 | 5000 |

| 3-6 | M3/6 | 3-6 | 4000 | |

| 3-7 | 3500 | |||

| W7 | 4-8 | M4/8 | 4-8 | 3000 |

| 4-9 | 2500 | |||

| W10 | 5-10 | M5/10 | 5-10 | 2200 |

| 6-12 | M6/12 | 5-12 | 2000 | |

| 8-12 | M8/12 | 6-12 | 1800 | |

| 7-14 | 1600 | |||

| W14 | M8/16 | 8-16 | 1500 | |

| 8-20 | 1300 | |||

| W20 | 10-20 | M10/20 | 10-20 | 1200 |

| 12-22 | M12/22 | 12-22 | 1000 | |

| 12-25 | ||||

| 15-25 | 900 | |||

| W28 | 20-30 | M20/30 | 20-30 | 800 |

| 22-36 | M22/36 | 22-36 | 700 | |

| 30-40 | 600 | |||

| 30-50 | ||||

| 36-54 | M36/54 | 36-54 | 500 | |

| 40-60 | ||||

| 50-70 | 400 | |||

| 54-80 | 325 | |||

| Note:QB/HH-2004 is the Huanghe Whirlwind Enterprise Standard. | ||||

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский