Unveiling the Versatile Applications of Diamond Micron Powder

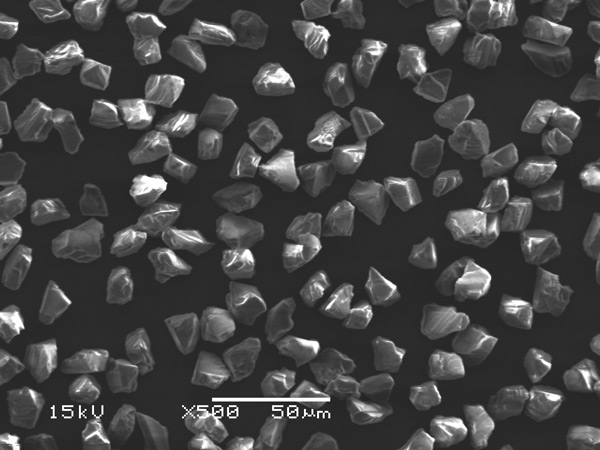

Diamond micron powder, also known as diamond micro-powder, is a fine, ultra-fine abrasive material that is widely utilized in various industries for a multitude of applications. Renowned for its exceptional hardness, abrasion resistance, and thermal conductivity, diamond micron powder is a cutting-edge abrasive material that offers superior performance in precision grinding, polishing, and surface finishing tasks.

1. Precision Grinding and Lapping

Diamond micron powder plays a crucial role in precision grinding and lapping applications, where tight tolerances and fine surface finishes are essential. The fine particles of diamond micron powder are used as abrasive agents in grinding wheels, cutting tools, and lapping compounds to achieve ultra-precise dimensions and mirror-like surface finishes on a wide range of materials, including metals, ceramics, and composites.

2. Polishing and Surface Finishing

In the jewelry, optics, and electronics industries, diamond micron powder is employed for polishing and surface finishing operations to achieve immaculate shine, clarity, and precision. The ultra-fine abrasive particles of diamond microns are capable of removing scratches, blemishes, and imperfections from delicate surfaces, such as gemstones, lenses, and electronic components, resulting in flawless and polished finishes.

3. Wire Drawing and Cutting Tools

Diamond micron powder is utilized in the manufacturing of wire drawing dies and cutting tools for its superior cutting efficiency, wear resistance, and durability. By integrating diamond micron powder into the tooling materials, manufacturers can enhance the cutting performance, tool life, and productivity of wire drawing dies, drills, and inserts, ensuring consistent and high-quality machining results.

4. Thermal Management and Electronics

Due to its excellent thermal conductivity and heat dissipation properties, diamond micron powder finds applications in thermal management solutions and electronics manufacturing. By incorporating diamond microns into thermal interface materials and electronic components, such as heat sinks and insulating substrates, engineers can improve the efficiency, reliability, and thermal performance of electronic devices and systems.

5. Composite Materials and Additive Manufacturing

In the aerospace, automotive, and defense industries, diamond micron powder is utilized in the production of advanced composite materials and additive manufacturing processes. The high hardness and abrasion resistance of diamond microns enable the reinforcement of composite structures and the enhancement of 3D-printed components, resulting in lightweight, strong, and high-performance materials for demanding applications.

The applications of diamond micron powder span a wide array of industries and processes, showcasing its versatility, precision, and performance capabilities as a cutting-edge abrasive material. From precision grinding and polishing to wire drawing and electronics manufacturing, diamond micron powder continues to redefine the standards of excellence in abrasive technology, offering innovative solutions for achieving superior quality, efficiency, and performance in diverse industrial applications. Huanghe Whirlwind is a professional diamond micron powder manufacturer in China, and our products are well-welcomed around the world. Contact us get inquiry now!

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский