Unveiling the Advantages of Cubic Boron Nitride (CBN) Powder: Revolutionizing Precision Machining and Material Processing

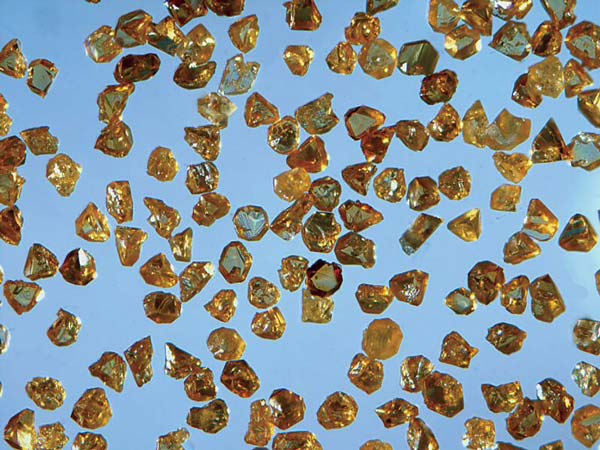

Cubic Boron Nitride (CBN) powder, a synthetic superabrasive material, has rapidly gained prominence in the manufacturing and machining industry for its exceptional properties and diverse advantages. From cutting tools to grinding wheels, CBN powder has revolutionized precision machining and material processing applications, offering a myriad of benefits that set it apart from conventional abrasive materials.

1. Unrivaled Hardness and Wear Resistance

One of the primary advantages of CBN powder is its unparalleled hardness, second only to diamond. This exceptional hardness translates into outstanding wear resistance, making CBN an ideal choice for machining hard and abrasive materials such as hardened steels, cast irons, and superalloys. Tools and components made with CBN powder exhibit extended tool life, reduced wear, and increased durability, resulting in lower maintenance costs and enhanced productivity.

2. Superior Thermal Stability and Chemical Inertness

CBN powder boasts superior thermal stability, allowing it to withstand high temperatures generated during machining processes without experiencing significant thermal degradation. This thermal resilience ensures consistent and stable performance even under extreme operating conditions, making CBN an excellent choice for high-speed cutting, hard milling, and other demanding applications. Additionally, CBN is chemically inert, resistant to chemical reactions, and does not react with most workpiece materials, contributing to its long-term reliability and performance consistency.

3. Enhanced Cutting Efficiency and Surface Finish

CBN powder’s precise crystal structure and sharp cutting edges contribute to enhanced cutting efficiency and exceptional surface finish quality. The ability of CBN abrasives to maintain sharpness over extended usage periods results in reduced machining forces, improved dimensional accuracy, and superior surface integrity. Whether used for grinding, turning, milling, or other machining operations, CBN powder consistently delivers high-precision results, making it a preferred choice for applications that demand superior surface quality and geometrical accuracy.

4. Versatility and Adaptability for Various Industries

Another notable advantage of CBN powder is its versatility and adaptability across a wide range of industries and applications. From automotive and aerospace to tool and die manufacturing, CBN powder finds diverse uses in precision machining, surface grinding, gear cutting, and other critical processes. The ability to tailor CBN powder properties such as particle size, crystal shape, and composition allows manufacturers to customize solutions that meet the specific requirements of different industries, resulting in optimized performance, cost-efficiency, and overall productivity.

5. Environmentally Friendly and Sustainable Solution

In addition to its performance benefits, CBN powder is also recognized for its environmentally friendly characteristics. Unlike traditional abrasive materials that may generate harmful dust or emissions during machining, CBN is a clean and sustainable option that minimizes environmental impact. Its longevity, durability, and recyclability contribute to a more sustainable manufacturing ecosystem, aligning with the growing emphasis on eco-friendly practices and responsible resource utilization in the industry.

The advantages of Cubic Boron Nitride (CBN) powder are vast and transformative, propelling the boundaries of precision machining and material processing to new heights. With its exceptional hardness, wear resistance, thermal stability, cutting efficiency, and versatility, CBN powder stands as a superlative choice for manufacturers seeking to achieve superior performance, quality, and efficiency in their machining operations. By harnessing the unique advantages of CBN powder, businesses can unlock a world of possibilities for innovation, productivity enhancement, and competitive differentiation in the dynamic landscape of modern manufacturing and engineering. Welcome to contact us to get free quotation at any time!

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский