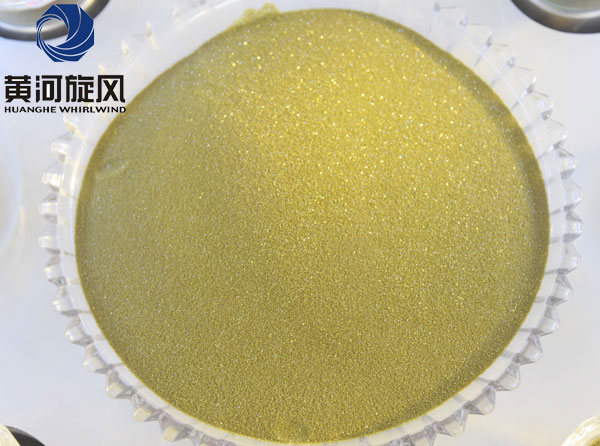

The Benefits of Industrial Diamond Powder: The Ultimate Abrasive Solution

Industrial diamond powder, often regarded as one of the most effective abrasive materials available, has become an indispensable resource across various industries. From manufacturing and construction to electronics and jewelry, the applications of diamond powder are vast and varied. Its unique properties provide a multitude of benefits, making it the preferred choice for companies seeking efficiency and precision in their operations.

1. Exceptional Hardness and Durability

One of the most notable characteristics of industrial diamond powder is its unparalleled hardness. Diamonds are the hardest known natural material, which makes diamond powder highly effective for grinding, cutting, and polishing a wide range of materials, including metals, ceramics, glass, and stone. This exceptional hardness allows for longer tool life and reduced wear on equipment, leading to lower maintenance costs and increased productivity.

2. Versatile Applications

Industrial diamond powder is incredibly versatile and can be used in various forms, such as abrasives, coatings, and even as a component in advanced composites. In manufacturing, it is commonly employed in grinding wheels, saw blades, and polishing compounds, enabling precise machining of intricate parts and surfaces. In electronics, diamond powder is utilized for heat sinks and substrates, enhancing thermal conductivity and improving device performance.

3. High Efficiency and Speed

The efficiency of industrial diamond powder is another key benefit. Its superior cutting and grinding capabilities allow for faster processing times compared to traditional abrasives. This increased efficiency is particularly advantageous in high-volume production environments, where time is of the essence. By reducing processing times, businesses can improve overall output and meet tighter deadlines.

4. Fine Particle Sizes for Precision Work

Industrial diamond powder is available in various grades and particle sizes, ranging from coarse to ultra-fine. This granularity allows for tailored applications, providing the right level of abrasiveness for specific tasks. Fine diamond powders are perfect for precision work, such as in the jewelry industry for polishing gemstones or in semiconductor manufacturing for creating smooth, defect-free surfaces.

5. Improved Surface Finish Quality

The use of industrial diamond powder leads to superior surface finishes, which are essential in many applications. The fine particles create a smooth, polished surface that not only enhances the aesthetic appeal of products but also improves their performance. For instance, in engineering applications, a better surface finish can reduce friction and wear, extending the life of components.

6. Reduced Environmental Impact

As industries strive to adopt more sustainable practices, industrial diamond powder offers an eco-friendly alternative to many traditional abrasives. Its long lifespan and high efficiency reduce the need for frequent replacements and excessive waste. Additionally, diamond powder can be used in water-based slurries, minimizing the environmental impact compared to solvent-based products.

7. Cost-Effectiveness

While industrial diamond powder may have a higher upfront cost compared to conventional abrasives, its long-term benefits outweigh the initial investment. The extended tool life, reduced processing times, and improved quality lead to significant cost savings over time. For businesses, this translates into enhanced profitability and a competitive edge in the market.

Industrial diamond powder is a game-changer across various sectors, providing unmatched hardness, versatility, and efficiency. Its ability to deliver high-quality results while minimizing environmental impact makes it a preferred choice for manufacturers and craftsmen alike. As industries continue to evolve and demand more advanced materials, the role of industrial diamond powder will only become more prominent, solidifying its status as the ultimate abrasive solution in modern manufacturing and construction. Contact us for free inquiry now!

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский