How Much Do You Know About Industrial Diamond Powder?

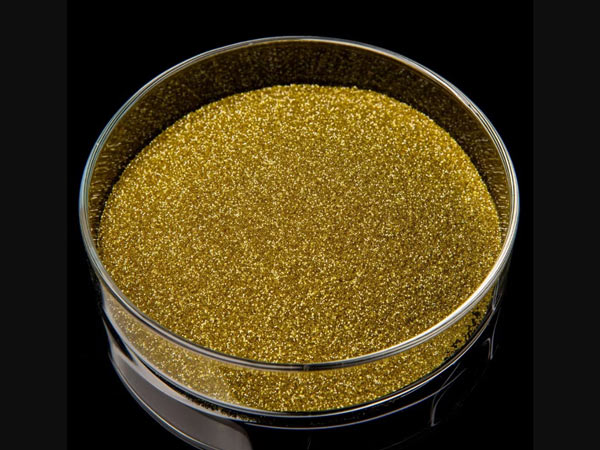

Industrial diamond powder, also known as synthetic diamond powder or micron diamond, is a finely ground form of diamond particles used extensively in manufacturing, machining, and precision engineering. Unlike gem-quality diamonds, industrial diamond powder is produced synthetically through high-pressure, high-temperature (HPHT) or chemical vapor deposition (CVD) methods, making it more cost-effective while retaining the exceptional hardness and thermal conductivity of natural diamonds.

Properties and Advantages

Diamond powder is renowned for its unmatched hardness (10 on the Mohs scale), making it ideal for cutting, grinding, and polishing ultra-hard materials such as tungsten carbide, ceramics, and glass. Additionally, its high thermal conductivity and chemical stability allow it to perform efficiently in high-temperature and corrosive environments.

Key advantages include:

– Superior Abrasive Performance: Diamond powder provides precise material removal with minimal surface damage.

– Long Service Life: Its extreme durability reduces the need for frequent replacement.

– Versatility: Available in various grain sizes (from nanometers to microns) to suit different applications.

Applications of Industrial Diamond Powder

1. Abrasive and Polishing Tools

– Used in grinding wheels, lapping compounds, and polishing pastes for optics, semiconductors, and precision components.

2. Cutting and Drilling Tools

– Enhances the performance of saw blades, drill bits, and wire saws for cutting hard materials like stone and composites.

3. Electronics and Semiconductors

– Applied in wafer dicing, thermal management, and as a dielectric material in advanced electronics.

4. Additives in Coatings and Composites

– Improves wear resistance in protective coatings and strengthens polymer composites.

5. Research and Development

– Used in high-precision experiments and nanotechnology applications.

Industrial diamond powder is a critical material in modern manufacturing, offering unparalleled hardness, durability, and precision. Its applications span multiple industries, from aerospace to electronics, making it indispensable for high-performance machining and advanced material processing. As technology advances, the demand for high-quality diamond powder continues to grow, reinforcing its role as a cornerstone of industrial innovation. Huanghe Whirlwind has over 30 years industrial diamond powder production experience that its products are very popular all over the world. Contact us for quote today!

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский