Factors to Consider When Buying Metal Powder: A Comprehensive Guide

In recent years, the demand for metal powders has surged, driven by advancements in additive manufacturing, powder metallurgy, and various industrial applications. Whether you are a manufacturer, researcher, or hobbyist, selecting the right metal powder is crucial for achieving optimal results in your projects. Here are several key factors to consider when purchasing metal powder.

1. Material Composition

The first and foremost factor to consider is the composition of the metal powder. Different applications require specific materials, such as stainless steel, aluminum, titanium, or cobalt. Understanding the properties of each material—such as strength, corrosion resistance, and thermal conductivity—will help you choose the right powder for your needs. Additionally, consider whether you need alloyed powders or pure metals, as this can significantly impact performance.

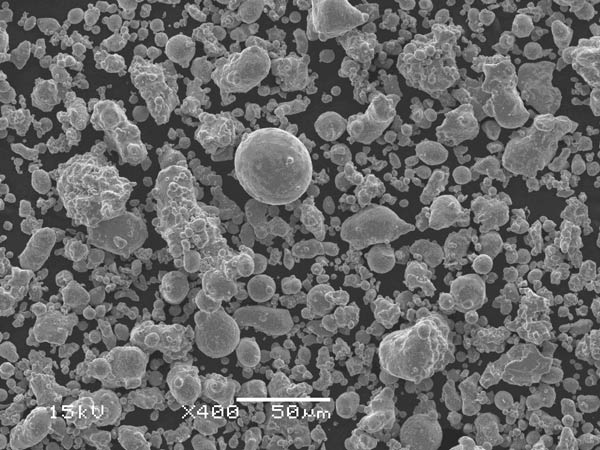

2. Particle Size and Distribution

The particle size and distribution of metal powder play a critical role in determining its flowability, packing density, and sintering behavior. Finer powders typically provide better surface finish and detail in additive manufacturing, while coarser powders may be more suitable for certain applications in powder metallurgy. It’s essential to review the manufacturer’s specifications regarding particle size distribution to ensure it aligns with your intended use.

3. Purity and Contaminants

The purity of metal powder is vital for achieving high-quality results. Impurities can adversely affect the mechanical properties and performance of the final product. When purchasing metal powder, inquire about the purity levels and any potential contaminants. Reputable suppliers should provide certificates of analysis to confirm the quality and composition of their products.

4. Production Method

Different production methods yield metal powders with varying characteristics. Common methods include atomization, mechanical milling, and chemical reduction. Each method has its advantages and disadvantages, influencing factors such as particle shape, size, and distribution.

5. Cost and Availability

Budget considerations are always important when purchasing metal powder. Prices can vary significantly based on material, quality, and supplier. It’s essential to balance cost with the quality and performance requirements of your project. Additionally, consider the availability of the powder, as lead times can impact your production schedule. Establishing a reliable relationship with suppliers can help ensure consistent access to the materials you need.

6. Supplier Reputation and Support

Finally, consider the reputation of the supplier from whom you are purchasing metal powder. Look for suppliers with a proven track record in the industry, positive customer reviews, and a commitment to quality. Good suppliers should also offer technical support and guidance to help you select the right powder for your application.

Purchasing metal powder is a critical decision that can significantly impact the success of your projects. By considering factors such as material composition, particle size, purity, production methods, cost, and supplier reputation, you can make an informed choice that meets your specific needs. Taking the time to evaluate these factors will ultimately lead to better performance, quality, and efficiency in your manufacturing processes. Welcome to contact us for more information and free inquiry at any time!

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский