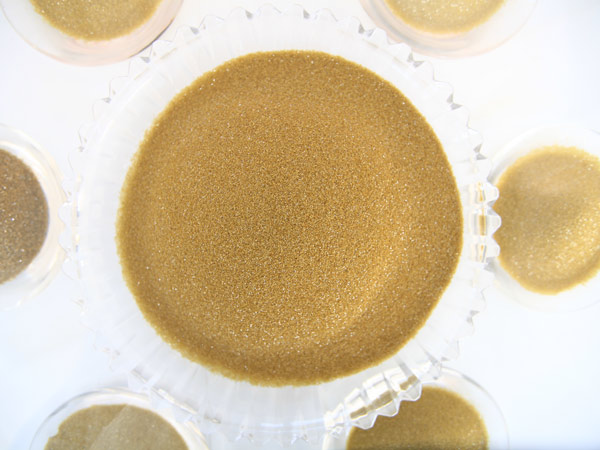

Effective Abrasive Material – Diamond Grit Powder

Diamond grit powder, a versatile and highly effective abrasive material, is widely used across various industries for cutting, grinding, polishing, and drilling applications. Composed of synthetic or natural diamond particles, this powder is renowned for its exceptional hardness, durability, and precision. As the hardest known natural material, diamond grit powder offers unparalleled performance in tasks that require precision and efficiency.

Composition and Manufacturing

Diamond grit powder is typically made from synthetic diamonds, which are produced under high-pressure, high-temperature (HPHT) conditions or through chemical vapor deposition (CVD). These synthetic diamonds are crushed and sieved into fine particles, ranging from microns to millimeters in size, depending on the intended application. The powder is graded according to particle size, shape, and concentration, ensuring it meets specific industrial requirements.

Applications

1. Cutting and Grinding Tools: Diamond grit powder is a key component in the manufacturing of cutting and grinding tools, such as diamond saw blades, grinding wheels, and drill bits. Its hardness allows it to cut through tough materials like concrete, glass, ceramics, and metals with ease.

2. Polishing and Lapping: In the optics and electronics industries, diamond grit powder is used for polishing and lapping surfaces to achieve a high level of smoothness and precision. It is particularly effective for polishing gemstones, lenses, and semiconductor wafers.

3. Construction and Mining: Diamond grit powder is integral to construction and mining equipment, such as core drill bits and wire saws, enabling efficient cutting and drilling through hard materials like rock and reinforced concrete.

4. Additive Manufacturing: In recent years, diamond grit powder has found applications in additive manufacturing (3D printing) to create composite materials with enhanced strength and wear resistance.

Advantages

Exceptional Hardness: Diamond grit powder outperforms other abrasives like silicon carbide or aluminum oxide due to its superior hardness.

Longevity: Its durability ensures a longer lifespan, reducing the need for frequent replacements.

Precision: The fine particles allow for precise and smooth finishes, making it ideal for high-precision tasks.

Diamond grit powder is an indispensable material in modern industry, offering unmatched performance in cutting, grinding, and polishing applications. Its unique properties make it a preferred choice for industries that demand precision, efficiency, and durability. Contact us for free quote and catalogue now!

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский