Applications and Advantages of Cubic Boron Carbide Powder

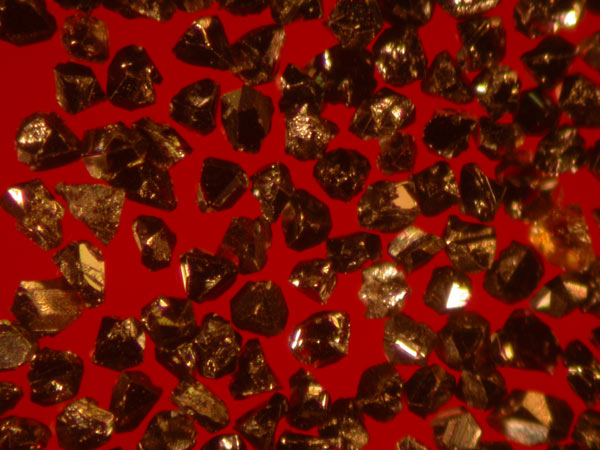

Cubic boron carbide (c-BC) powder is a remarkable synthetic material that has garnered significant attention in various industries due to its exceptional properties. Composed of boron and carbon atoms arranged in a cubic crystal structure, this material is renowned for its extreme hardness, thermal stability, and chemical inertness. These characteristics make cubic boron carbide powder a versatile and valuable material in a wide range of applications.

Applications of Cubic Boron Carbide Powder

1. Abrasive and Cutting Tools

Cubic boron carbide is one of the hardest known materials, second only to diamond. This makes it an ideal choice for abrasive and cutting tools. It is widely used in grinding, polishing, and cutting applications, particularly for materials that are difficult to machine, such as hardened steels, ceramics, and composites.

2. Wear-Resistant Coatings

Due to its high hardness and wear resistance, cubic boron carbide powder is used in the production of wear-resistant coatings. These coatings are applied to components subjected to extreme wear and tear, such as industrial machinery parts, cutting tools, and mining equipment, significantly extending their service life.

3. Nuclear Industry

Cubic boron carbide has excellent neutron absorption properties, making it a crucial material in the nuclear industry. It is used in control rods, shielding materials, and other components in nuclear reactors to manage and absorb neutron radiation, ensuring safe and efficient operation.

4. Electronics and Semiconductors

The thermal stability and electrical insulating properties of cubic boron carbide make it suitable for use in high-temperature electronic devices and semiconductors. It is also being explored for use in next-generation electronic components that require materials capable of withstanding extreme conditions.

5. Aerospace and Defense

In the aerospace and defense sectors, cubic boron carbide is used in the manufacture of lightweight, high-strength components. Its ability to withstand high temperatures and resist wear makes it ideal for use in turbine blades, armor plating, and other critical applications.

Advantages of Cubic Boron Carbide Powder

1. Exceptional Hardness

Cubic boron carbide is one of the hardest materials known, making it highly effective in abrasive and cutting applications. Its hardness ensures that tools and coatings made from this material maintain their edge and performance over time.

2. Thermal Stability

The material retains its properties at high temperatures, making it suitable for use in environments where other materials would degrade. This thermal stability is particularly valuable in high-temperature industrial processes and aerospace applications.

3. Chemical Inertness

Cubic boron carbide is chemically inert, meaning it does not react with most chemicals. This property makes it ideal for use in corrosive environments and in applications where chemical resistance is critical.

4. Lightweight

Despite its hardness, cubic boron carbide is relatively lightweight. This combination of strength and low weight is advantageous in applications where weight reduction is important, such as in aerospace and automotive industries.

5. Neutron Absorption

The material’s ability to absorb neutrons without forming long-lived radioactive isotopes makes it invaluable in the nuclear industry for radiation shielding and control.

Cubic boron carbide powder is a highly versatile material with a wide range of applications across various industries. Its exceptional hardness, thermal stability, chemical inertness, and neutron absorption properties make it a material of choice for demanding applications. Henan Huanghe Whirlwind is a professional cubic boron carbide powder manufacturer that produces top-notch super-hard material products. Contact us for free inquiry now!

Inquiry

Please leave us your requirements, we will contact you soon.

English

English Español

Español Русский

Русский